|

| June 16, 2020 | Volume 16 Issue 23 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Graphene-reinforced carbon fiber: Cheaper, stronger for car and aero parts

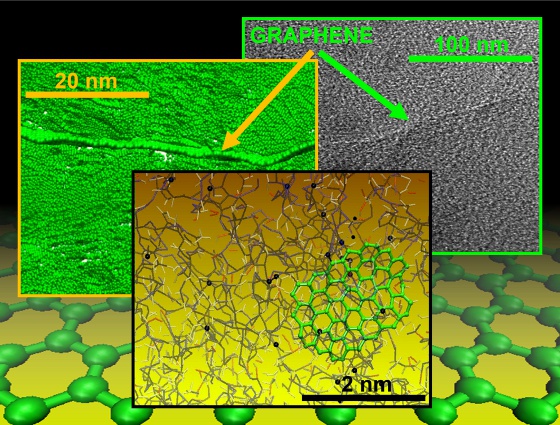

Using lab experiments and computer simulations (shown here), a team of researchers found that adding graphene to the carbon fiber production process greatly strengthens the material, and this may one day pave the way for higher strength, cost-effective car materials. [Credit: Margaret Kowalik and Adri van Duin, Penn State.]

By Liam Jackson, Penn State

A new way of creating carbon fibers, which are typically expensive to make, could one day lead to using these lightweight, high-strength materials to improve safety and reduce the cost of producing cars, according to a team of researchers at Penn State. Using a mix of computer simulations and laboratory experiments, the team found that adding small amounts of 2D graphene to the production process both reduces the production cost and strengthens the fibers.

For decades, carbon fibers have been a mainstay of airplane production. If created in the right way, these long strands of carbon-based atoms, narrower than human hair, are lightweight, stiff, and strong -- a perfect application for keeping passengers safe in a vehicle soaring miles above the ground.

"Even though carbon fibers have really nice features, they would make a car far more expensive" with the way carbon fibers are manufactured now, said Adri van Duin, professor of mechanical and chemical engineering, Penn State. "If you can get these properties easier to manufacture, then you can make cars significantly lighter, lower the cost of them, and make them safer."

Carbon fiber sells for about $15 per pound today, and the team, which includes researchers from Penn State, the University of Virginia, and Oak Ridge National Laboratory, in collaboration with industry partners Solvay and Oshkosh, wants to reduce that to $5 per pound by making changes to the complex production process. A lower production cost will increase carbon fiber's potential applications, including in cars. Further, the team's research may lower the cost of producing other types of carbon fibers, some of which sell for up to $900 per pound today.

"Currently, most carbon fibers are produced from a polymer known as polyacrylonitrile, or PAN, and it is pretty costly," said Małgorzata Kowalik, researcher in Penn State's Department of Mechanical Engineering. "The price of PAN makes up about 50 percent of the production cost of carbon fibers."

PAN is used to create 90 percent of carbon fibers found in the market today, but its production requires an enormous amount of energy. First, PAN fibers have to be heated to 200 to 300 C to oxidize them. Next, they must be heated to 1,200 to 1,600 C to transform the atoms into carbon. Finally, they have to be heated to 2,100 C so that the molecules are aligned properly. Without this series of steps, the resulting material would lack its needed strength and stiffness.

VIDEO: Shown is a computer simulation of adding graphene to the process of growing carbon fibers. [Credit: Margaret Kowalik and Adri van Duin, Penn State. Simulation was produced by ReaxFF software run on Penn State's supercomputing systems.]

The team reported in a recent issue of Science Advances that adding trace amounts of graphene -- only 0.075 percent concentration by weight -- to the first stages of this process allowed the team to create a carbon fiber that had 225 percent greater strength and 184 percent greater stiffness than the conventionally made PAN-based carbon fibers.

The team gleaned insight into the chemical reactions taking place through a series of small- and large-scale computer simulations conducted on several supercomputers.

"We connected experiments of different scales to not only show that this process works, but it gave us an atomistic-scale reason why these types of additives work," said van Duin.

The flat structure of graphene helps to align PAN molecules consistently throughout the fiber, which is needed in the production process. Further, at high temperatures graphene edges have a natural catalytic property so that "the rest of PAN condenses around these edges," said van Duin.

With the new knowledge gained from this study, the team is exploring ways to further use graphene in this production process using cheaper precursors, with a goal of cutting out one or more of the production steps altogether, thereby reducing costs even more.

The U.S. Department of Energy and NSF supported this research.

Published June 2020

Rate this article

View our terms of use and privacy policy